Complete: Unique Robot Project Full Operational at Rauma Sawmill

Nyheter

“This is a technology boost for the sawmills,” says Bernt-Ove Andersson, Marketing Manager at Renholmen.

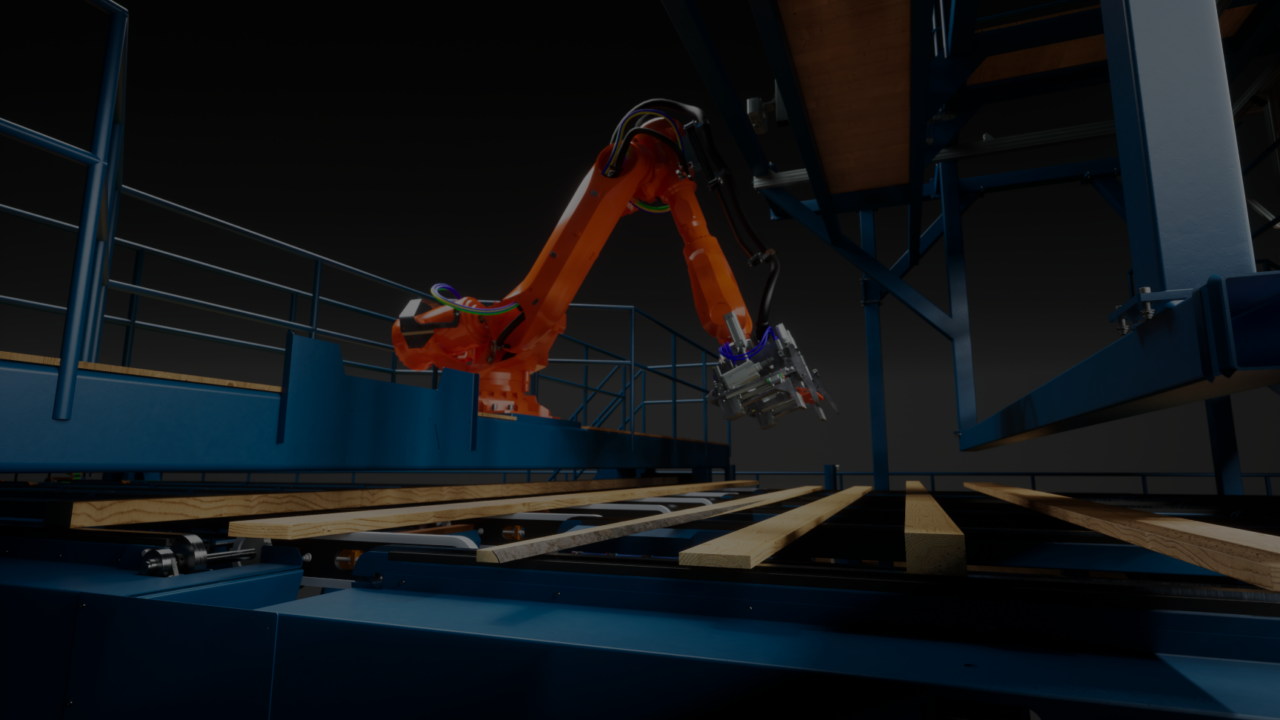

Together with Finnish Metsä Fibre, Renholmen has developed a system that makes it possible to process timber at the sawmills without operators being physically at the line. The joint development project is called Robovision System (ROSY), and has now been installed at Metsä’s sawmill in Rauma, Finland.

“This is a revolutionary product that streamlines timber processing, increases safety, and improves the work environment,” says Bernt-Ove Andersson, Marketing Manager at Renholmen. “ROSY detects and handles all timber pieces that may cause disturbances later in the process. Defective timber pieces that are bent, twisted, or broken are lifted out of the flow, and pieces that are incorrectly placed in the flow are automatically corrected.”

Renholmen has installed six robots in the facility in Rauma – two robots in green sorting, two on the stick placer, and two in the grading mill, where one is used for grading and one for packing. The robots are fully operational and approved.

“The robots, which are located where the operators normally stand, monitor the flow and deal with defective bits and so on. Thanks to the robots, the operator can instead sit in a control room and monitor the process on screens,” says Andersson.

Above all, the robot installation improves the work environment. When operators work out in the sawmill, they are exposed to dust, noise, draughts, and are required to wear protective equipment such as hearing protection and safety goggles. The work environment in the control room is much better for the operators.

“In addition, the risk of accidents is reduced, such as crushing injuries to hands between planks on the belt,” says Andersson.

But there is also an economic aspect to it all. Each robot has taken over from an operator, which for Rauma corresponds to six persons – in five shifts around the clock.

“Now only one person needs to be on-site per shift to monitor the process,” says Andersson. “It also minimises the human factor – that an employee is tired at four in the morning and does not notice a defective piece. In such a case, the belt must be stopped for a period of time to solve the problem, which reduces efficiency. The robot system improves monitoring.”

Robots can be found in other applications at sawmills, such as for filling up material, but using robots to replace operators at timber processing operator stations is wholly unique.

“ROSY will change the way timber is processed forever. It is a real technology boost for the sawmills,” concludes Bernt-Ove Andersson.